I have been a hardware engineer for 13 years in Japan, especially automotive industry for a long time.

I have spent more time with automotive parts suppliers than with the car manufacturers themselves.

This story is TOYOTA MOTOR CORPORATION and TOYOTA's group.

TOYOTA is way too huge!

Toyota Motor Corporation and the Toyota Group are also known as giants.

It is well known that the company originally started with Sakichi Toyoda's invention of the loom.

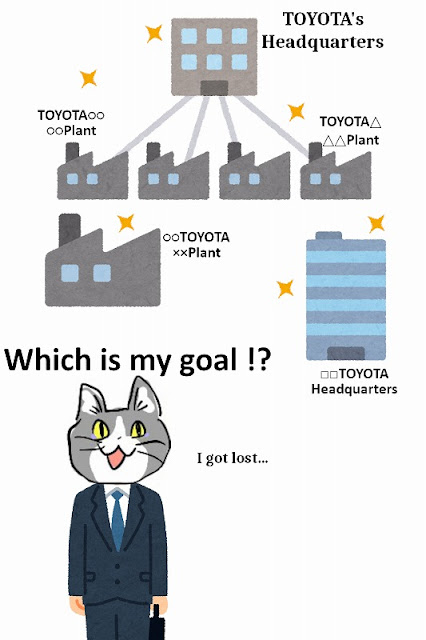

Today, Toyota is world-renowned, but there are too many related companies and factories.

In addition, each company had many factories, and when we visited them, we panicked, wondering which company had which factory! I used to panic when I visited them.

Since they are concentrated around Toyota City, it is easy to make a mistake because the addresses are similar....

I used to go to Chiryu or Tsuchihashi station by train and rent a car.

Melting pot of people

The Toyota Group is said to have 2.8 million people in the entire group.

Many people emphasize the three actual principles of genba, genri, and genri, but there are too many people to make a general statement.

However, among the many car manufacturers, I think they were the most enthusiastic about kaizen.

I was packaging engineer, so they requested me lots of Kaizen proposal.

The results were mixed, but I felt that there was a good reason for the continued profit, not just a temporary gain.

As a supplier, I had a hard time because of the strict cost requirements...

TOYOTA cars are highest quality

Not only have I worked in the automotive industry, but I also like cars.

I often visit dealers to compare cars, and I have the impression that Toyota cars are suitable for everyone.

When I test drove a Prius for the first time, I felt that the ride was very soft.

When I continued to drive the C-HR, I felt that the gas pedal was very responsive, the speed increased as much as I stepped on it, and the steering wheel had a large buffer.

I had the impression that the car was absorbing all the mistakes of my poor driving.

I felt that the level of perfection of the C-HR was so high that I decided to purchase the C-HR.

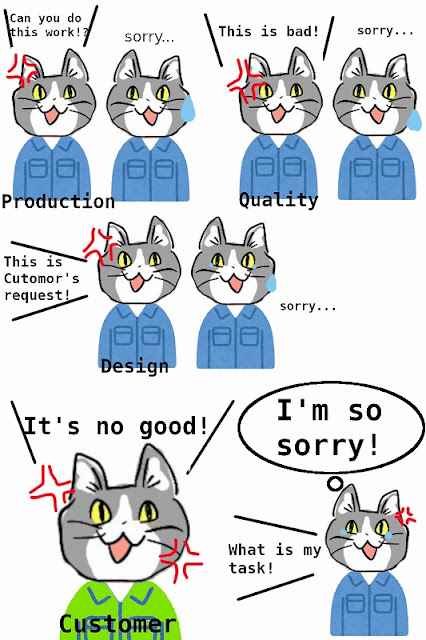

I often cry as a supplier just because they don't compromise on quality.

At the time when we handled seat belts, the cloth parts of seat belts were visible to customers, so scratches and even wrinkles were not allowed.

Since metal and cloth parts are mixed together, the cloth parts were vulnerable to damage, and reducing the number of products in a single box would increase transportation costs, making it difficult to balance quality and cost.

Conclusion

I really can't say anything about them because they are so huge, but I feel that all companies share the same commitment to the customers who buy cars from them.

I have many good and bad memories of Toyota, but I think that if I were to buy a car, I would choose Toyota next time.

That is how uncompromising the company is in its work.

Toyota Motor Corporation is always included in the ranking of companies that other people are envious of, but that's not surprising.

Thanks for reading!

コメント

コメントを投稿