Is there the Fate of Manufacturers? What is the sorting process?

Sorting, which is to pick and choose things, is a word that scares manufacturers as much as it does.

It's a word that can scare the heck out of manufacturers, especially those in manufacturing and quality assurance.

In this article, we will talk about such sorting work.

What is sorting?

Sorting is the process of separating good products from the rest.

If there are products that do not meet the specifications, it is necessary to separate the good ones from the bad ones and ship only the good ones.

This is the sorting process.

In most cases, defects are reported by the customer or discovered during the internal inspection process.

If it is found internally, it is still a problem, but if the customer contacts us, it is a big problem.

This is because a large number of products that are not originally intended for shipment have been produced and distributed.

Generally, manufactured products are stored in a warehouse called a depot, where they are opened and sorted one by one.

Where will it be done?

If it is found within the company, it is done in a corner of the in-house factory, but if it is discovered by a report from the customer, it is done at an outside warehouse.

If it is discovered by a report from the customer, it is done at a warehouse outside the company.

In other words, it is an overnight business trip.

Furthermore, if the factory to which we deliver the products is a car manufacturer, the number of deliveries per day will be extraordinary, so we will have to continue sorting for a long time.

Warehouses are better than outdoors because they have roofs, and there is no air conditioning.

It is hot in summer and cold in winter.

In addition, it is very difficult when the percentage of good products is low, and it is difficult to get good products in the middle of the process.

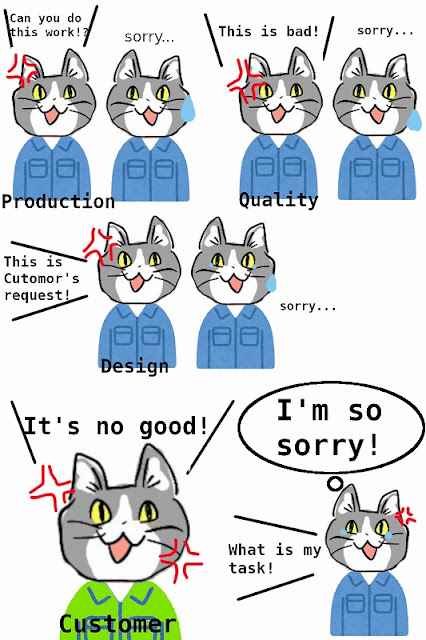

Although most of the sorting work is done by the quality assurance department, it is sales and production control who negotiate with customers, so we received a lot of phone calls without hesitation while we were working.

Sales: "Can't you do it yet!"

Worker: "We're working on it!

Both sides were in a state of "Don't you even know what we're up to! It is a barren battle.

Even when done in a thermostatic chamber

If defects cannot be found in an environment at room temperature, sorting may be performed by exposing the product to temperatures as low as minus several degrees Celsius or as high as plus 80 degrees Celsius.

Products are exposed to a thermostatic chamber in a harsh environment for 30 minutes to 2 hours.

The products are a disaster, but so are the people.

It is the manufacturer's responsibility, but once you have experienced it, you will never want to do it again.

The quality assurance department is responsible for that hated sorting on a daily basis.

I have worked for a total of four manufacturers and there is not a single company that does not have a sorting process.

There are specialized contractors.

The discovery of a glitch is always sudden, as there is no warning in advance.

We have to go sort it out, but we don't have the manpower! When this is the case, an outside contractor is called in to do the sorting.

There is a company that specializes in doing this on behalf of the manufacturer, and Greentech is well known in the industry for the quality of its workers.

GreenTech is well known in the industry for the quality of its workers and the many times we have worked with them.

Greentech is a large company with over 3,000 employees and has a company car with the company logo on it.

Whenever I saw the car in the office, I thought something was wrong, but I always pretended I didn't know.

Conclusion

Unfortunately, there is no such thing as a defect-free manufacturer.

Rather than deliver inferior products to users, this sorting process is a waterfront operation that is carried out with the utmost care.

Since only those who know the products and have a certain level of skill can engage in this work, the labor cost tends to be high, but it is also a chance to become more familiar with the products.

It is also easy to become friends with the people you work with.

If you have the opportunity, you might want to raise your hand.

Thanks for reading!

コメント

コメントを投稿