The inside story of HONDA

Honda has developed a wide range of businesses, including motorcycles, automobiles, marine (outboard motors), and jets, with overwhelming technological prowess.

In this second story of our behind-the-scenes look at the auto parts industry, I'll talk about Honda.

No telework! Thoroughly on-site-oriented

Starting after the Golden Week holidays in 2022, Honda has abolished telework and stipulated that employees will, in principle, come to work five days a week.

This was controversial because it is backwards from the times and will make it difficult to secure a diverse workforce, but the manager felt that it is typical of Honda.

Like Honda's founder, Soichiro Honda, many Honda employees are craftsmen who focus on the field.

It depends on the department, but I guess the intention is to make it easy to go to the site even for a short time at the factory.

Or perhaps they emphasized face to face work.

However, the automotive industry tends to dislike teleworking, as seen in the case of Elon Musk's decision to discontinue teleworking at Tesla, forcing employees to come to work or resign.

The company I used to work for also had a minimum number of workdays per week, but the minimum varied from office to office, from a minimum of two days per week in urban offices to four days per week in rural offices.

As a person who loves teleworking and wants to be allowed to do whatever I want, I found the four-day workweek to be a bit of a squeeze....

I wish they would look at whether we are producing results, not whether we are working or not.

Respect for suppliers.

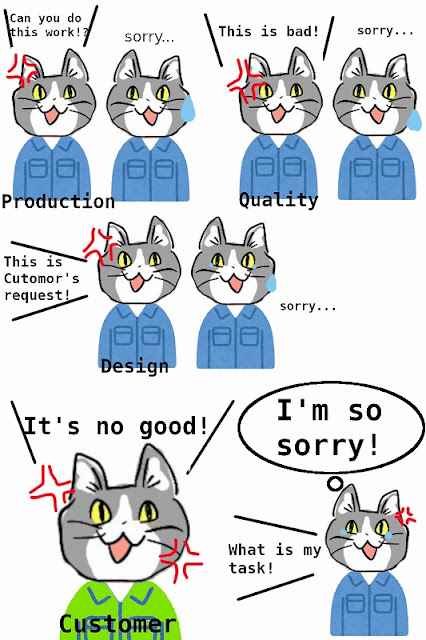

The illustration at the beginning is a true story.

I had previously received an offer to hold a cargo shape review meeting at a Honda plant, so I visited the plant with samples in hand.

Honda has two factories in Japan, Yorii in Saitama Prefecture and Suzuka in Mie Prefecture.

I had visited both factories, but the factory staff were often busy and sometimes there were unexpected problems, so not all the people scheduled to attend the study meeting were able to gather.

Then, the person in charge of Honda called the various places and said

If you don't show up after we've invited you, let's make a decision with the members who have gathered here.

He strongly promoted the study group.

I was almost moved to tears by this response, as some car makers may have to wait until a later date, or even keep a sample of the product for review.

Suppliers are also human beings, and it is human nature to want to repay them with sincerity.

After the packing form was safely decided and mass production started, we received various suggestions for improvement of the packing form, which we responded to with sincerity.

However, there was one thing that made Honda's suppliers weep.

It's unusually difficult to get into a factory ...

Both the Yorii and Suzuka factories are very large and highly classified.

Naturally, entry requires passing through a security gate, but the guards here were very strict and made it difficult.

There are certain procedures and dress codes for outside contractors, and if they do not meet at least one of them, they are not allowed to enter.

When I first arrived, I was unaware of these procedures and contacted the person in charge.

I was called in and thought, "I'm here on business, too, so there's no need for them to be so rude..."

Also, the factory grounds are ridiculously large.

It was difficult to walk around with sample boxes, each weighing nearly 10 kilograms.

Conclusion

I visited Honda's Yorii Plant, Suzuka Plant, and Hamamatsu Plant for marine business.

I felt the enthusiasm for automobiles, but at the same time, I had a sense of fear for the suppliers. Because this would make it easier to find glitches!

Honda and Mazda are the only Japanese automakers that manufacture their own transmissions.

Both are famous for their enthusiastic users, and it is this kind of dedication to car manufacturing that continues to attract not only ordinary users but also core fans.

Honda continues to do well with its lineup of mini cars such as the N-BOX series, SUVs such as the Vezel, and EVs such as the Honda-e.

I hope that Honda will continue to lead the Japanese manufacturing industry.

Thanks for reading!

コメント

コメントを投稿